“Out of clutter, findsimplicity. From discord, find harmony. In the middle of difficulty lies opportunity.” — Albert Einstein AND

“Great things are done by a series of small thingsbrought together.” – Vincent Van Gogh,Dutch artist

Merged by Future State Partners

In my recent exploratory conversation with a team made up of CEO, COO, General Manager, Operations Managers of a Manufacturing, Maintenance and Supply Chain Organization in Sydney, we all faced with a situation, where wanted to start Site lean Assessment alongside with our team at Future State Partners. The GOAL of this exercise is as to discover opportunities of improvement within the prioritised areas of this business.

Before we could begin our journey, we needed to prioritize the areas of business. This took us to a very basic question, which area of this business are value adding or non-value adding from their customer perspective

I will try my best to answer the above question, as this one question, I have been asked several times, so please sit tight.

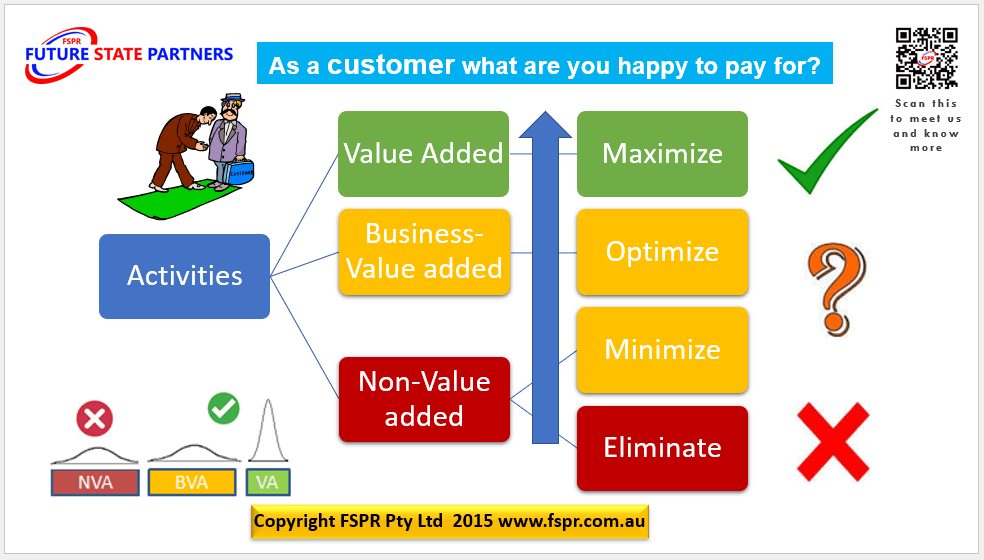

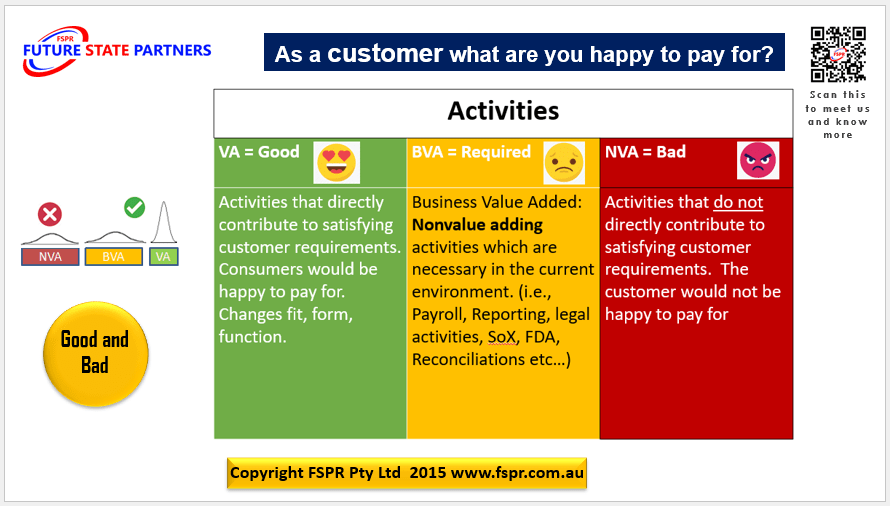

Just to recall, the value in business is defined as “Anything which a customer is willing to pay for” As we all would appreciate that, any business is filled with both value-adding and non-value activities

This invited a quick question, Is there abetter way to handle Non-Value Adding activities? If yes, who in the business had onus to handle this properly.

For all the avid readers

Please feel free to book a exploratory conversation on how to bring your vison to life with

practicable change strategies, please click here

Our Mission at Future State Partners

We are on a mission to make happier workplaces a reality by empowering our community to conduct positive improvements and changes independently both at work and personal lives

Learn more about conducting or benefitting from lean site assessments by contacting our expert Practitioners by emailing us (info@fspr.com.au) or calling us (02 8311 8100(24X7))

How to lead the way and create a best-in-class culture by using regular Lean site assessments?

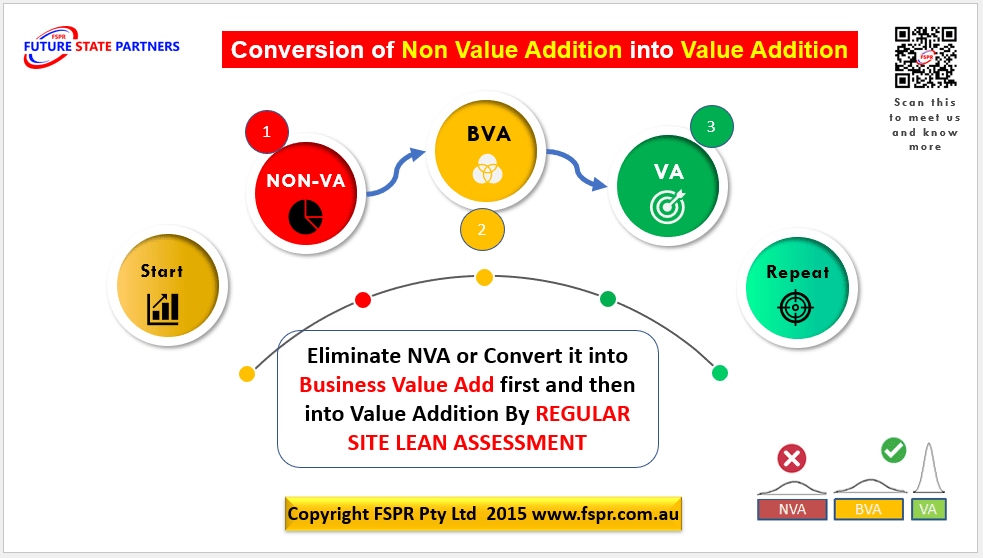

On further discovery with the CEO, Operations Managers, General Managers, it was explored that,there is huge opportunity of converting /eliminating Non-Value addition NVA) into Business Value adding (BVA) first and then into Value addition (VA).

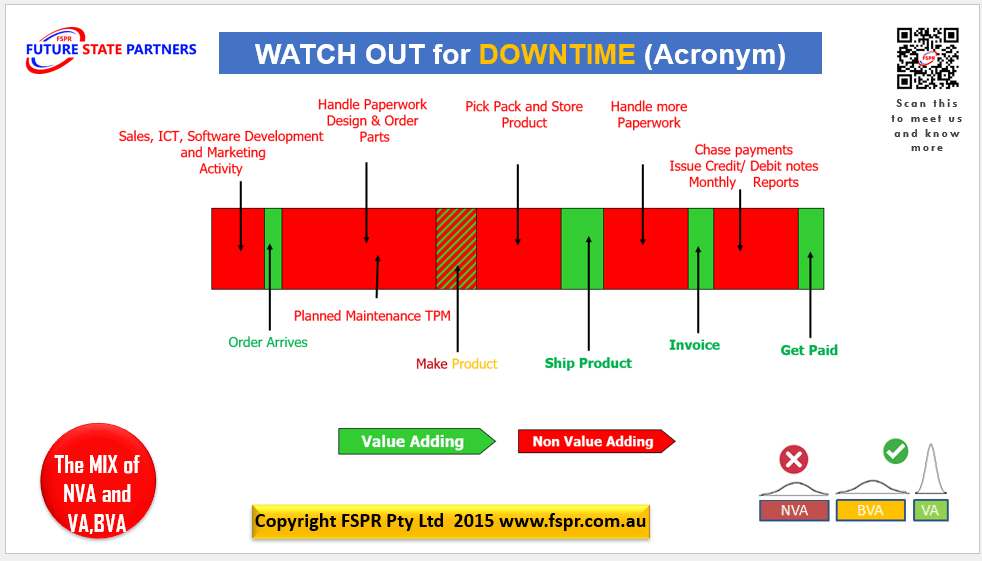

All the activites (VA,NVA,BVA) are filled with DOWNTIME Wastes .Please check the infographic above and below this

In addition, as most of us would appreciate the fact that there is continuous live conversion of value adding activities into non-value addition activities is happening on every hour basis without even we are realising it, we find ourselves as team in a situation where we end up adding lesser value for our customers and eventually get phased out of the business canvas.

The need is to counter-balance this situation with Regular Lean Assessments (Contact us by Clicking here or call us on 0283118100 (24X7)) of your service/product/site/floor/customer/warehouse/manufacturing/business segment etc. to answer "Where to accurateley start the journey of Improvements from"

One of the biggest challenges would be to come up with a cultural shift underpinned by accurate

change that is required to sustain any solution envisaged that stays longer, just like we did for this large Australian Manufacturing, Maintenance & Supply Chain and Logistics organisations resulting in their increased ability to serve more customers with the same resources

bringing up overall happiness amongst team members

How to maximise the gains using well understood change journey today?

Do you want to knw a best way to remain competative and win against uncertainity? .

We would love to hear your story during a exploratory conversation , so please don't hesitate to book in for one now (please click here or email us info@fspr.com.au) to reach out experts at Future State Partners and Practioners .

We would love to make it easier for you in the same way we have helped so many leaders and team members in their journey towards change that can last for longer term results

Ready to start on your own?

This is a super good news that you have decided to take the first step and we appreciate you and your teams in taking first step. You are not alone and we would encourage you to use live support from our industries leading practioners by accessing accurate template library for free. Please click here to access them.